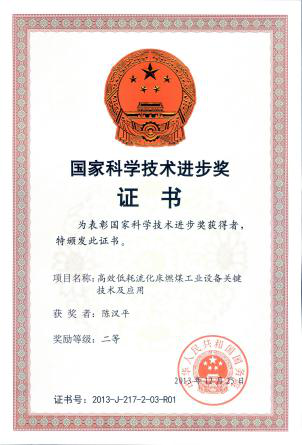

The Second-class Awards of National Scientific and Technical Progress (2013)

Considering the large demand of energy resources and emission reduction in industrial boilers and kilns, circulating fluidized bed boiler (CFBB) and high temperature flue gas furnace (HTFST) show the advantages of efficient, clean, and the comprehensive utilization of carbon-contained solid fuels. In SKLCC, novel CFBB and HTFST technologies were innovated in term of Chinese fuel properties and independent intellectual property rights, such as high efficient separation circulating combustion, low-energy consumption in intensification combustion and the high quality comprehensive utilization of carbon-contained solid fuels, which have been developed based on the key technical problems through over 20 years research work. These technologies have been commercialized and used widely in industry. It is significant to the retrofit of the energy-saving and emissions reduction technology for many industrial facilities.

These technique has been applied in Jianglian Heavy Industry Co., Ltd, and Huangshi Building Materials Co., Ltd, and many other companies. It is widely used in thermal, chemical, building materials, metallurgical and other industries. There are more than 5000 end-users, which are widely spread in China and more than 20 countries and areas in Asia, Europe, Africa and America. This technique played an important role for Huangshi in Hubei province to become the famous brand in high-temperature gas furnace, and it has presented extremely high competitiveness. In recent three years, more than 12295 steam tons boiler capacities and 485 sets HTFSF were produced by only two boiler companies and two furnace companies, respectively. Over 6.293 billion and 2.133 billion of profits and new tax revenues were obtained, respectively. Overall, remarkable economic, social and environmental benefits have been achieved.